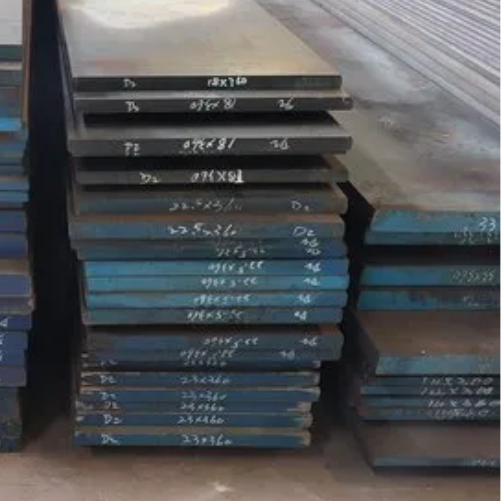

D3 High Carbon Chromium Flats in Bhosari

D3 High Carbon Chromium Flats Manufacturer And Supplier in Bhosari

Usha Metal Industries Private Limited is a trusted manufacturer and supplier of D3 High Carbon Chromium Flats in Bhosari, Pune, known for delivering exceptional quality products. Our D3 Flats are designed for superior hardness, excellent wear resistance, and high strength, making them ideal for industrial tooling, molds, and die-making applications. Each product is crafted with precision to ensure durability and reliable performance in demanding environments. With a commitment to quality and timely delivery, Usha Metal Industries stands as a preferred choice for D3 High Carbon Chromium Flats in Bhosari, Pune, meeting diverse industrial requirements.

Technical specification of D3 High Carbon Chromium Flats

| Property | Specification |

|---|---|

| Material | D3 High Carbon Chromium Steel |

| Grade | D3 |

| Standard | ASTM, DIN, JIS (Customer-Specific) |

| Shape | Flat Bar |

| Thickness | 10mm – 300mm (Custom sizes available) |

| Width | 50mm – 400mm (Custom sizes available) |

| Length | 1000mm – 6000mm (Custom lengths available) |

| Hardness | 58–62 HRC (After Heat Treatment) |

| Tensile Strength | 1700 MPa |

| Yield Strength | 1200 MPa |

| Elongation | 12–14% |

| Density | 7.85 g/cm³ |

| Heat Treatment | Quenching and Tempering (Customized) |

| Surface Finish | Polished, Smooth, or as per customer requirement |

| Applications | Tooling, Dies, Molds, High-Strength Components, Industrial Machinery |

Features of D3 High Carbon Chromium Flats

- D3 High Carbon Chromium Flats offer superior wear resistance, extending the lifespan of tooling and molds.

- The material maintains its hardness even under high-temperature conditions, ensuring optimal performance.

- These flats are ideal for precision machining and complex industrial applications.

- With excellent machinability, D3 Flats can be easily processed to meet specific design requirements.

- The high carbon content contributes to the product’s exceptional strength and resistance to deformation.