Hot Die Steel Bar manufacturer and supplier in Behala

Hot Die Steel Bar manufacturer and supplier in Behala

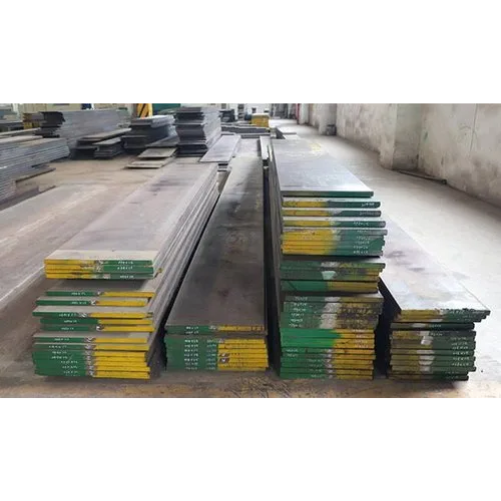

Usha Metal Industries Private Limited stands out as a leading manufacturer and supplier of Hot Die Steel Bars in Behala. Known for our commitment to quality and innovation, we deliver Hot Die Steel Bars that excel in durability and performance. Crafted with precision engineering and advanced metallurgical techniques, our bars are ideal for demanding industrial applications. Whether for tooling, die casting, or forging, Usha Metal Industries ensures each bar meets stringent quality standards, providing reliability and longevity. Trust us for Hot Die Steel Bars that empower your projects with strength and resilience.

Technical specification of Hot Die Steel Bar

| Parameter | Specification |

|---|---|

| Material Grade | Hot Die Steel |

| Standard | ASTM A681, DIN 1.2344, JIS SKD61 |

| Chemical Composition | Carbon (C): 0.35-0.42%, Silicon (Si): 0.80-1.20%, Manganese (Mn): 0.25-0.50%, Chromium (Cr): 4.75-5.50%, Vanadium (V): 0.80-1.20%, Molybdenum (Mo): 1.10-1.50% |

| Hardness | 48-52 HRC |

| Heat Treatment | Annealing, Stress Relieving, Preheating, Hardening, Tempering |

| Physical Properties | Density: 7.85 g/cm³, Melting Point: 1426°C, Thermal Conductivity: 30-35 W/m·K |

| Mechanical Properties | Tensile Strength: 1800-2100 MPa, Yield Strength: 1600-1800 MPa, Elongation: 8-12%, Impact Toughness: 20-25 J/cm² |

| Applications | Hot and cold work tooling, Die casting dies, Extrusion tools, Forging dies, Plastic molds |

| Available Forms | Round bars, Flat bars, Plates, Blocks, Custom shapes upon request |

| Surface Condition | Black, Peeled, Machined, Polished |

Features of Hot Die Steel Bar

- Our Hot Die Steel Bars are engineered with precise metallurgical control to optimize toughness and reduce brittleness under high-stress conditions.

- They undergo a specialized heat treatment process to enhance thermal stability and maintain dimensional integrity during prolonged use.

- Usha Metal Industries ensures each bar is subjected to rigorous testing for internal soundness and surface quality, ensuring superior performance in critical applications.

- These bars feature a unique grain structure refinement that improves machinability and facilitates smoother finishing processes.

- We offer customized surface finishes to meet specific industrial requirements, enhancing corrosion resistance and extending service life.